MarkForged

Technical Details

Model: Desktop Mark Two

Materials available: Onyx, PLA, TPU

Datasheet: View Here Official Handbook: View Here

Loading Filament

Set up plastic for loading

- Disclaimer: Material is moisture sensitive, exposure to moisture for a long period of time may cause printing issues so be careful when handling.

- Open the drybox and remove the spindle inside. Pull the magnetic cap and body apart.

- Remove Spool from sealed packaging, place the dessicant packs inside drybox to further absorb moisture.

- Place spool on spindle and attach magentic cap.

- Place spool on drybox, making sure that the filament is exiting from the top

- Feed the plastic filament all the way through the transparent tube at one end of the drybox until it reaches one end of the extruder. Let it hang freely for now.

- Close drybox, make sure the latches click twice

Quick Loading

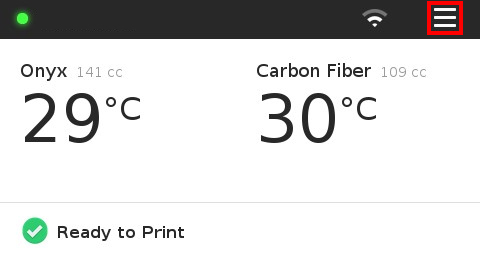

- Use the touchscreen menu in the lower center of the printer, select the menu icon at the top left corner.

- On menu tile, select Materials option.

- Select Load Material to begin loading.

- Select Quick Load and then choose the type of plastic you’re working with. (If you are not loading a full spool, click on Meter Loading instead)

- Wait for printer to heat up and press Next

- The filament should start moving through the plastic tube to the extruder, you can lift the lid on the printer to check that it’s happening correctly.

- Use tweezers to break any excesss from the extruder and click Done to finish process.

Unloading Filament

- Open the touchscreen meny in the lower center of the printer, select the menu icon at top left corner.

- On menu tile, select Materials option.

- Select the Unload Plastic tile to begin unloading. Click Next when prompted

- Open the lid at the top to reveal the plastic feed tube. Push in the black push-to-connect fitting to release tube from back of extruder.

- Open the drybox where material is located, wind the plastic back onto spool and remove spindle with unused filament to dispose.

- Unscrew and remove bowden tube (gold screw) from the front of extruder. Press Next to begin spelling out the filament.

- Press Stop on the touchscreen when all of the filament is out of the extruder

- Reinstall the plastic tube from both sides of the extruder. Press Next

- Press Load Plastic or skip depending on what you want to do.

- If you pressed skip click yes to start the cooldown process.

- Press Done to exit.